The evolution of frame repair technology has drastically changed the automotive industry, empowering specialists with advanced tools like laser measurement systems and robotic welding machines. These innovations enable faster, more precise bumper repair and frame restoration work, setting new standards globally for auto body shops. Modern frame repair processes, once manual and labor-intensive, now incorporate sophisticated equipment to meet the complex needs of modern vehicles, ensuring optimal results after any collision. This technology benefits customers by reducing costs and enhancing vehicle safety.

The art of frame repair has undergone a remarkable evolution, driven by technological advancements that have transformed the industry. Modern frame repair specialists now leverage advanced equipment to achieve unprecedented levels of precision and efficiency. From laser alignment systems and hydraulic presses to computer-aided design (CAD) software, these innovations enable specialists to tackle complex repairs with finesse. Moreover, safety and quality assurance have never been better, thanks to specialized tools that guarantee consistent outcomes and protect both the vehicle and its owners. This article explores these game-changing advancements, shedding light on how advanced equipment is redefining the landscape of frame repair for good.

- The Evolution of Frame Repair Technology

- – A brief history of frame repair and its transformation over time

- – Introduction of modern tools and their impact on precision and efficiency

The Evolution of Frame Repair Technology

The evolution of frame repair technology has come a long way since the traditional methods used in auto body shops. Today’s advanced equipment has revolutionized the way frame repair specialists work, enabling them to deliver precision and efficiency like never before. Modern frame repair specialists now have access to sophisticated tools designed specifically for complex metalwork, allowing them to accurately assess and rectify damage caused by collisions or accidents.

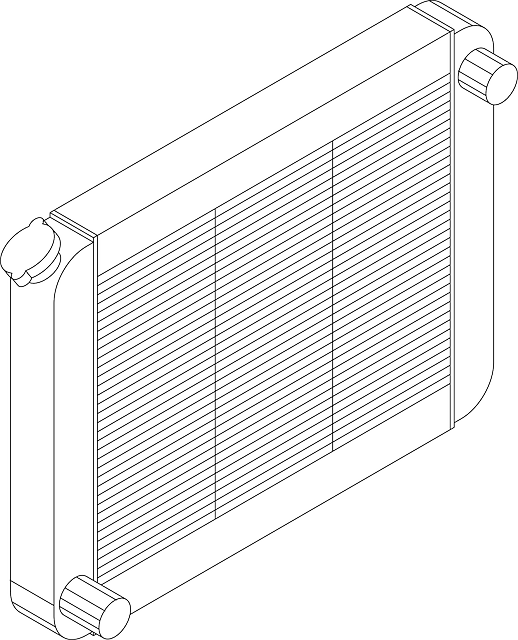

These innovations include state-of-the-art laser measurement systems that capture precise dimensions of the vehicle’s frame, ensuring minimal errors during the repair process. Additionally, robotic welding machines have made their way into many auto body shops, offering enhanced accuracy and consistency in joining metal components, a far cry from manual welding techniques. This shift towards technology has not only improved the speed of collision repair but also boosted the overall quality of bumper repair and frame restoration work, setting new standards for auto body shops worldwide.

– A brief history of frame repair and its transformation over time

The art of frame repair has evolved significantly over the years, reflecting the advancements in vehicle technology and the increasing demand for precise, high-quality work. Historically, frame repairs were often manual processes, with specialists using hand tools to realign and straighten damaged vehicle frames. This labor-intensive approach required skilled artisans who could meticulously gauge and adjust metal components.

However, as vehicles became more complex with the introduction of advanced safety systems and lightweight materials, the need for specialized equipment emerged. Modern frame repair specialists now rely on a range of sophisticated tools and techniques, transforming the once-artisanal trade into a highly technical endeavor. Today’s auto collision centers employ state-of-the-art machinery, such as computer-aided precision measuring devices and robotic welding systems, to ensure accurate vehicle restoration and seamless results in every vehicle collision repair.

– Introduction of modern tools and their impact on precision and efficiency

The evolution of technology has significantly transformed the landscape of frame repair, empowering modern specialists with advanced tools that enhance precision and efficiency. Frame repair specialists now boast a sophisticated arsenal of equipment designed to tackle complex auto collision center challenges with remarkable accuracy and speed. These innovative tools enable them to perform intricate tasks such as straightening bent metal, replacing damaged components, and ensuring structural integrity with unmatched finesse.

The introduction of state-of-the-art machinery has revolutionized collision repair processes, elevating the standard of care in auto dent repair. Through the utilization of advanced sensors and computer-aided technology, frame repair specialists can now precisely measure and analyze damage, leading to more accurate repairs and reduced time spent on laborious manual adjustments. This not only benefits customers by minimizing costs but also guarantees that their vehicles are restored to their pre-accident condition, restoring peace of mind and safety on the road.

Modern frame repair specialists leverage advanced equipment to achieve unparalleled precision and efficiency. The evolution of frame repair technology, driven by innovative tools, has revolutionized the industry, setting new standards for quality and speed. These specialists now employ state-of-the-art machinery that not only streamlines the repair process but also ensures minimal impact on the environment, making them true masters of their craft in the contemporary automotive landscape.